Metal Samples along with Sensor Networks Inc., offers smartPIMS® non-intrusive ultrasonic corrosion/erosion monitoring products.

Smarter Remote Non-Intrusive Corrosion Monitoring with Installed Ultrasonic Sensors

Take advantage of remarkably cost-effective, modular and robust solutions for remote, non-intrusive monitoring of ID corrosion and erosion using the latest solid-state electronics, wireless or wired technologies, cloud based software and innovative ultrasonic transducer designs. |

|

The versatility and ease of use is amazing!

- Calculating corrosion rates

- Monitoring known “low spots” or “areas of interest”

- Using a non-invasive solution in lieu of or in conjunction with invasive methods (coupons, ER probes, etc.)

- Reducing recurring access costs

- Continuously accessing additional & improved data on asset condition

|

Installed sensors are ideally suited for remotely monitoring areas of active metal loss due to corrosion/erosion. |

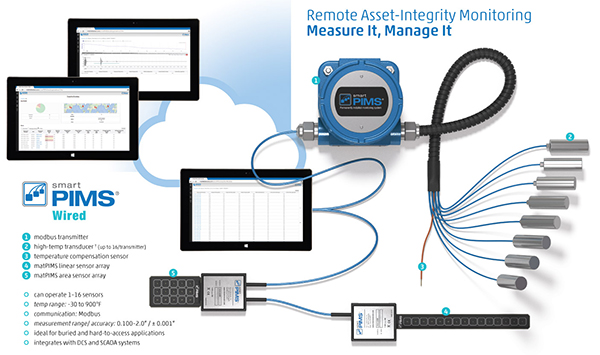

| smartPIMS components, software, and systems are highly configurable, from just a few sensors to thousands of TMLs per network. Leveraging the low-cost and ubiquitous aspects of the Internet and wireless networks (including cellular) systems can be easily and cost-effectively installed and maintained at most industrial facilities. |

|

smartPIMS Datalogger

- Operates on battery (2 years at 1 reading/day).

- Stores 3000 readings (each w/ time, date, waveform).

- Connects via Modbus (RS-485) to tablet/PC.

- Offloads data to dataPIMS software which can export to an XML/CSV file and/or upload to web PIMS via Internet connection.

- Offers 16 single- or 8 dual-element UT probe channels.

- Transducers maintain 1 mil (0.001” / 0.025mm) resolution and 0.040” (1mm) minimum wall thickness.

- Transducers withstand -22°F (-30°C ) to 932°F (500°C).

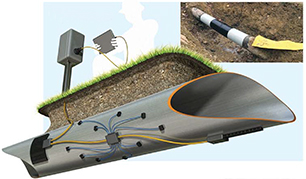

- Sensors install buried or above-ground, temporarily or permanently.

|

|

|

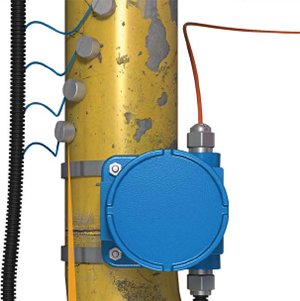

smartPIMS Modbus

- Hard wired – (for areas without cellular or wireless infrastructure)

- No battery on board

- Collected data manually via tablet/PC

- ‘Daisy-chain’ up to 32 DSIs on 1000’ RS-485 cable

- Choose between 16 single element or 8 dual element sensors per DSI

- Temporary or permanently affix the sensors

|

|

smartPIMS Cellular

- Wireless

- Ideal for testing a few to a moderate number of points

- Simple to install

- Takes readings instantly upon setup at defined intervals (1 per day/week/month/etc.)

- Cellular IoT connection – Little to no IT support needed

- Cloud-based back end for analysis and trending & spreadsheet data exporting capability

- Low cost, highly configurable

- Battery life: 5-7 years

|

|

smartPIMS Transducers

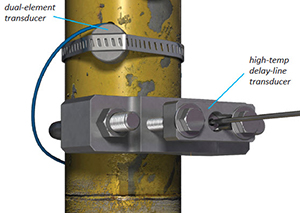

The smartPIMS® product line has 2 different ultrasonic transducer types: dual-element and delay-line.

Each “sensor” type should be selected based largely on temperature range, number of point to be monitored and the severity of the expected metal loss.

|

|

|

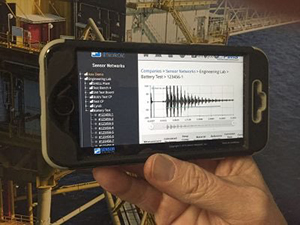

| webPIMS

AWS-hosted cloud-based data management system for ultrasonic thickness measurements from installed UT sensors.

- Access with most any web browser

- View, report, analyze the data

- Remote collaboration with multiuser access

- Data can be hosted by Sensor Networks or by user

- Short-term and long-term corrosion rates

- Set alarms for assets

- Identify by GPS sensor coordinates

- A-scan viewing

|

|

|

Why Ultrasound?

- Safe; Non-invasive to the asset’s pressure boundary

- Absolute in its ability to directly measure remaining wall thickness (not a proxy for wall loss) at the sensors point of contact

- Extremely accurate to 0.001” (0.025 mm), with the ability to measure down to 0.040” (1 mm) in carbon steel, especially for fixed-location probes

- Rugged, reliable and portable

- Low recurring maintenance costs

- Versatile and cost-effective

|

Typical Applications

Power Gen

- Flow Accelerated Corrosion (FAC)

- Microbiological corrosion

- High pressure steam lines

- High point vent

- Baseline of new assets

Oil & Gas

Downstream

- Replacement of invasive technologies – ER probes/coupons

- Process control for chemical inhibitor optimization

- High Temp Naphthenic acid monitoring

Midstream

- Post repair or replacement baseline of new infrastructure

- Monitoring of known/existing localized corrosion events

- Used in lieu of pigging/ILI for river/road crossings or 49 CRF 192 & 195

Upstream

- Wellhead monitoring for initial start-up & injection/storage

- High pressure pumping instrumentation health monitoring

- Sand erosion/wash-out for offshore platforms & FPSOs

Other Applications

- Flow-Accelerated Corrosion (FAC)

- Microbiologically-Induced Corrosion (MIC)

- High-pressure steam lines

- High point vent

- Baseline of new assets

|

|

|