Type:

Model:

Application:

Overall (dia. x h):

Probe face (dia.):

Active area (dia.):

Cable exit:

Rigid stem length:

Resolution:

Thickness range**:

Temp. range:

Frequency:

Active Area (dia.):

Overall (dia. x h):

# of transducers:

Cable length:

Weight (w/ housing):

Coupling:

Mounting:

|

High-Temp

Dual-Element

XD-301

Severe corrosion

1.25” x 1.0” (31.8 x 25.4mm)

0.43” (11mm)

0.375” (10mm)

90 deg. (side)

n/a

0.001” (0.025mm)

0.040 - 6.0” (1.0 - 150.0mm)

-22 to +275°F (-30 to + 135°C)

5 MHz

0.375” (10mm)

0.75” x 0.75” (19 x 19mm)

1-8

10’ (3m), 25’ (7.62m), 50’ (15.24m)

7 oz. (200 g)

temporary: Stopaq (<200°F / <93.3°C)

semi-permanent epoxy

magnet and/or band clamp |

Ultra-High-Temp

Single-Element

Delay-Line

XD-201

Ultra-High-Temp

0.8” x 2.4” (20.3 x 61.0mm)

0.6” (15.2mm)

0.375” (10mm)

0 deg. (top)

13” (330mm)

0.001” (0.025mm)

0.125 - 1.0” (3.0 - 25.0mm)

-22 to +932°F (-30 to 500°C)

7 MHz

0.375” (10mm)

0.8” x 2.25” (20.3 x 57.2mm)

1-16

10’ (3m), 25’ (7.62m), 50’ (15.24m)

varies with clamp size

temporary/permanent

U-bolt or band clamp |

| Hazardous rating: |

UL-CSA Class I Div II, Groups A-D, T4, ATEX/IEC Ex Zone 2 and Japanese Certified |

| * minimum resolutions stated as typical values, but will vary with pipe condition |

|

|

| Epoxies (for use with high-temp dual element only) |

| |

EA-9394 |

EA-9394 C2 |

Cure temp.:

Operating temp.:

Misc.: |

77-200°F (25-93°C)

-20 to +300°F (-28 to +150°C)

mixing solution for up to 8 sensors |

200-350°F (93-177°C)

-20 to +400°F (-28 to +204°C)

mixing solution for up to 8 sensors |

|

|

|

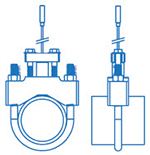

Mounts |

|

|

|

| Type: |

Magnetic |

Banded Clamp |

U-Bolt Clamp |

| Attributes: |

Ease of installation & relocation |

Stability, ease of installation & relocation |

Ultra-high temps, maximum stability |

| |

|

|

|

| |

Dimensions: |

5.9" x 1.95" x 2.9"

(150 x 50 x 74mm) |

9.25” x 1.75” x 2.6”

(235 x 44.5 x 66mm) |

| |

Weight: |

6 lbs (2.75 kg) |

10 lbs (4.54 kg) |

|